Automated Electromagnetic Transportation System

An innovative automated transportation system that leverages electromagnetic forces to move small items along a track. This project demonstrates the application of Lorentz Force principles in practical automation, offering a scalable alternative to traditional conveyor systems for small product movement.

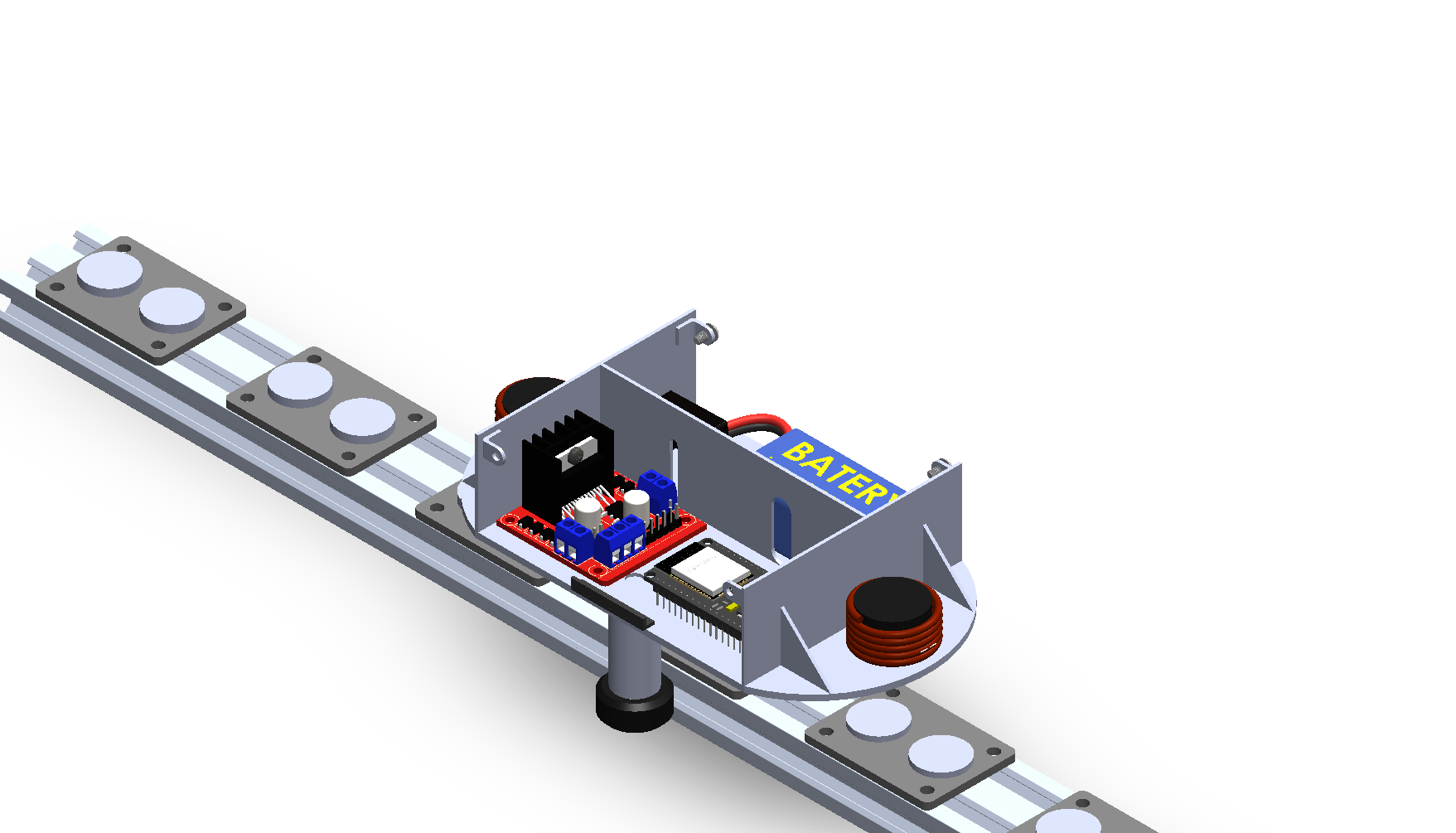

CAD Renders

How It Works

Lorentz Force Principle

The system operates on the fundamental principle of the Lorentz Force, where a charged particle moving through a magnetic field experiences a force perpendicular to both the velocity and magnetic field directions. In this application, controlled electric current creates the necessary electromagnetic interaction to propel the platform.

Visualizing the Lorentz Force

The Lorentz force acts perpendicular to both the velocity of a charged particle and the magnetic field. In this example, the magnetic field points into the page, the particle moves to the right, and the force is upward (for a positive charge).

System Components

ESP32 Microcontroller

Controls the H-bridge circuit to toggle current flow direction and magnitude, enabling precise acceleration, propulsion, and deceleration of the platform.

H-Bridge Circuit

Enables bidirectional current flow through the electromagnetic coils, allowing for forward and reverse motion control.

Magnetic Track

The track is embedded with permanent magnets that create the necessary magnetic field for the Lorentz Force interaction.

Moving Platform

A small platform equipped with electromagnetic coils that carries a tote for item transportation.

Technical Implementation

- Control System: ESP32 microcontroller manages the entire operation

- Power Management: H-bridge circuit controls current flow direction and intensity

- Magnetic Field: Permanent magnets embedded in the track provide the required magnetic field

- Motion Control: Variable current flow enables precise speed and direction control

- Load Capacity: Small item tote mounted on the platform for product transportation

- Bidirectional Operation: System can move items in both directions along the track

Project Inspiration

This project was inspired by my experience working in automation at Caterpillar. During my time there, I observed that expanding and rerouting traditional conveyor systems was extremely costly and often not economically viable for moving small products. The high costs and inflexibility of conventional conveyor systems motivated me to explore alternative solutions.

The electromagnetic transportation system addresses these limitations by creating a modular, infinitely expandable solution where motion is purely dependent on individual units rather than complex mechanical infrastructure.

Key Advantages

- Infinite Scalability: Simply extend the track length to expand the system

- Bidirectional Operation: Items can be moved in both directions along the track

- Modular Design: Individual units operate independently, reducing system complexity

- Cost Effective: Significantly lower infrastructure costs compared to traditional conveyors

- Flexible Layout: Easy to modify and adapt to changing production needs

- Precise Control: Electronic control enables fine-tuned speed and positioning

- Low Maintenance: Fewer moving parts compared to mechanical conveyor systems

Future Development

- Integration with industrial automation systems

- Advanced control algorithms for optimal energy efficiency

- Multi-platform coordination for complex routing

- Sensor integration for collision avoidance and positioning

- Wireless communication between platforms

- Scalable manufacturing for commercial applications